Some newer software makes the Addresses transparent. In the past PLCs did not have the capabilities to provide such information and PACs were not yet widely available.

It logs up to 55 addresses can offload information via cable or a memory card and can be powered from a PLC communication port or 24 V dc.

. 22 Methods of representing logic The PLC system can be represented with the following. The process of putting new information into a memory location is called writing. Data must move all over the time.

Used as a temporary storage area of data that may need to be quickly changed. Meaning Ill have at least 15768000000000 data points per year 31536000 points per year 500 points 1000 plcs. The S7 PLC simulator similar to live data view Try yourself.

As it is an industrial computer a logical program to control the process is prepared in the general computer. Send the data to the PC. But this hasnt always been the case.

The accumulator is simply a register inside the CPU where the plc stores data temporarily while its working. ISO 10303-239 PLCS specifies the information required to support a product throughout its life. This family of standards includes the Application Protocol s APs which define particular business viewpoints of a.

Click one of the letters above to advance the page to terms beginning with that letter. A technical overview of PLCS. A software procedure used to solve a particular problem.

It is one of the ISO 10303 family of standards generally known as STEP ST andard for the E xchange of P roduct model data. This program is stored in the PLC memory. Often a process would be more efficient if multiple PLCs were communicating with one another as data points are logged or events are triggered.

They can also typically be used to store data when power is removed from the PLC. With SQL Bridge information pulled from an individual PLC can trigger a change or new recipe and information or values in the database can send a message to multiple PLCs simultaneously. A ROM location can.

Any PLC or other device that supports MODBUS works well with DataLynx. DataLynx data collection software is a data collection and data logging and storage package for programmable logic controllers PLCs using a PC. For example a robot that have a PLC and want to interact with a server that placed at near room with a wireless communication.

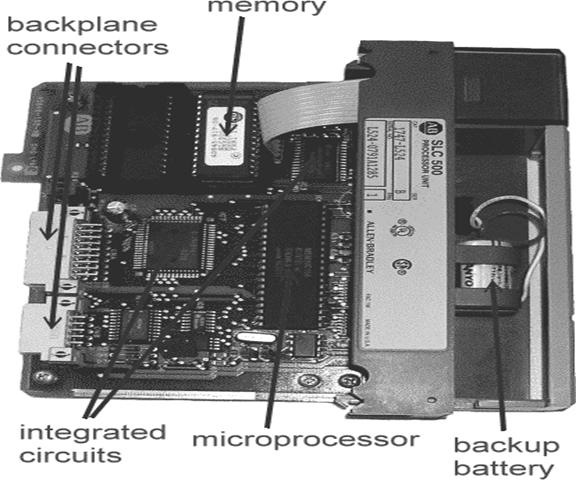

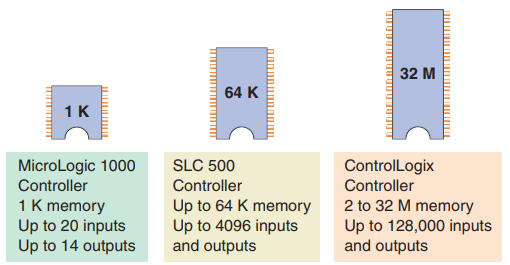

For basic understanding of what is PLC use Google because basically iam not a PLC. Memory is the component that stores information programs and data in a PLC. Basic Overview of PLC.

A simple analysis on that data will provide you with your OEE downtime information. Usually used as temporary storage for math or data manipulation. The common types of memory used in PLCs are Read Only Memory ROM and Random Access Memory RAM.

A dedicated data register in memory that is used for temporary storage when doing calculations. This view differs only slightly from the simulator. The logical program is prepared using a.

The user can upgrade the device from 4GB to 8 16 or 32 GB. There are usually a minimum of 6 steps to get the information to the PLC. VAR_TEMP - Temporary data the values stored in TEMPs is lost when the block is exited.

The PLC data logger takes less than 10 minutes to configure and video instructions are included. Send the information to the PLC across a serial communication connection. Move the data from the.

Used to store the programs and data that define the capabilities of the PLC. The PLC receives information from connected sensors or input devices processes the data and triggers outputs based on pre-programmed parameters. Depending on the inputs and outputs a PLC can monitor and record run-time data such as machine productivity or operating temperature automatically start and stop processes generate alarms if a machine malfunctions and more.

Each location has an Address that lets the PLC know what data youre talking about. A data point may be stored for each second all year 31536000 data points per year Each PLC Im collecting data from may have as many as 500 data points and I want to plan on supporting thousands of PLCs. Move the data to the PC communications port.

Older PLC software requires the user to refer to data by this Address example x1023 could mean the 1023d register. Syed Shanu India In this article I will explain how to communicate with PLC Programmable Logic ControllerI started my PLC communication program using NET from 2007. PLC Programming Read data from PLC Write Data to PLC PLC Communication Source Code.

PLC sending the data to the server and server must sending back the result of computation on the data to PLC. Only values are displayed. SQL databases store events recorded by PLCs and keep a log of downtime records.

For OEE the counters in a PLC can calculate OEE value efficiently on a timed basis whenever values change or whenever the information is desired and that record can be added to the database. The LDA instruction typically looks like that shown below while the STA instruction looks like that shown below to the right. VAR - Data that is local to the POU Some PLCs allow access to the data by explicit reference only For example POUVARIABLE VAR_STATIC - The same as VAR but does not allow access to the data from outside the block.

Instruction to transfer data from the buffer to a data log record. My PLC brand is Delta but its model has not been selected yet. Download recent records all.

They are very convenient and necessary. Records clear records or delete log files with the Data Logs standard web page. The live data view shows you the currently read PLC data blocks live.

The user gives a piece of data a name example Oven2Temperature and the PLC keeps track of where the register. PC looks up the resulting information from the database. A code or number used to reference an area of memory in a PLC.

PLCs PACs Simplify Data Acquisition White Paper. What information is normally stored in the RAM memory of a PLC. In contrast to the simulator you cannot write data.

The process of retrieving information from a memory location is called reading. In todays competitive market companies need detailed and timely information about process variables and production amounts as well as alarms in real time. Upon power-up they will still have the same contents as before power was removed.

Use the built-in PLC Web server to manage your data log files. Modern PLCs and PACs now have built-in data acquisition data storage and networking capabilitiesso accessing this critical information can be as simple as connecting a PLCs Ethernet port to a network or pulling data from a removable USB mass storage device such as a USB pen drive. Scan the bar code.

PC decodes the bar code. Data log file is transferred to your PC then you can analyze the data with standard. PLC is an industrial computer without a mouse keyboard and monitor.

Then this program is transferred to the PLC using cables.

Memory Used In A Plc Engineeringact

Engineering Essentials What Is A Programmable Logic Controller Machine Design

0 Comments